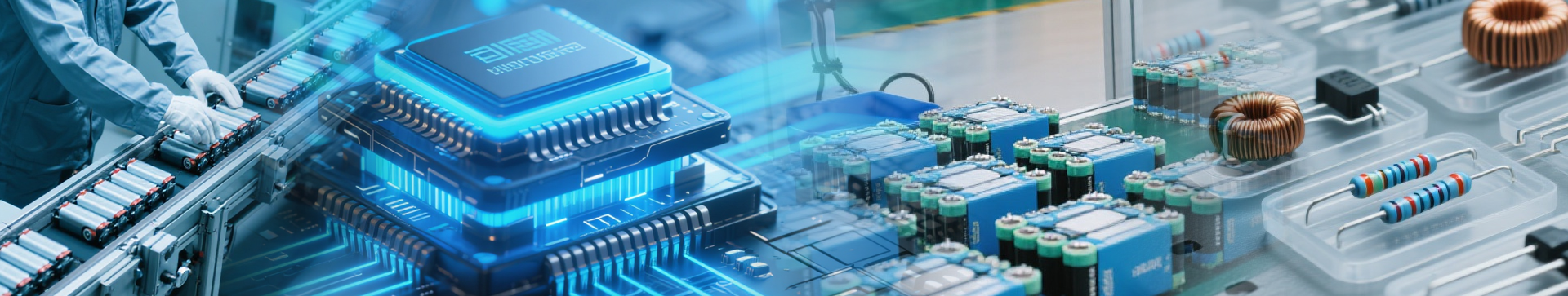

>Company Introduction

Yuanhe Machinery Technology Co., Ltd. was established in 2017. Its main products include semiconductor pipeline accessory parts series, photovoltaic production parts, non-standard vacuum chambers, etc. It is widely applied in industries such as semiconductor manufacturing, photovoltaics, and university laboratories. With long-term experience in manufacturing vacuum components, the company is equipped with a variety of processing equipment such as MAZAK and CNC, as well as TIG precision welding equipment, and imported measuring tools, helium mass spectrometry leak detection, spectrometers and other measuring devices. The company's quality policy: Serve customers with quality. Win the market with quality. We always carry out continuous quality improvement and personnel training in management to ensure that our products meet the quality requirements of customers and provide them with perfect services.

>A corner of the workshop |

|

With the ability of "non-standard customization+standardized quality control", Yuanhe Workshop has delivered high reliability products to multiple leading semiconductor factories, photovoltaic leaders, and top universities. With the craftsmanship of "millimeter level precision and nanometer level cleanliness", it has become a trusted choice for the manufacturing of high-end equipment core components.

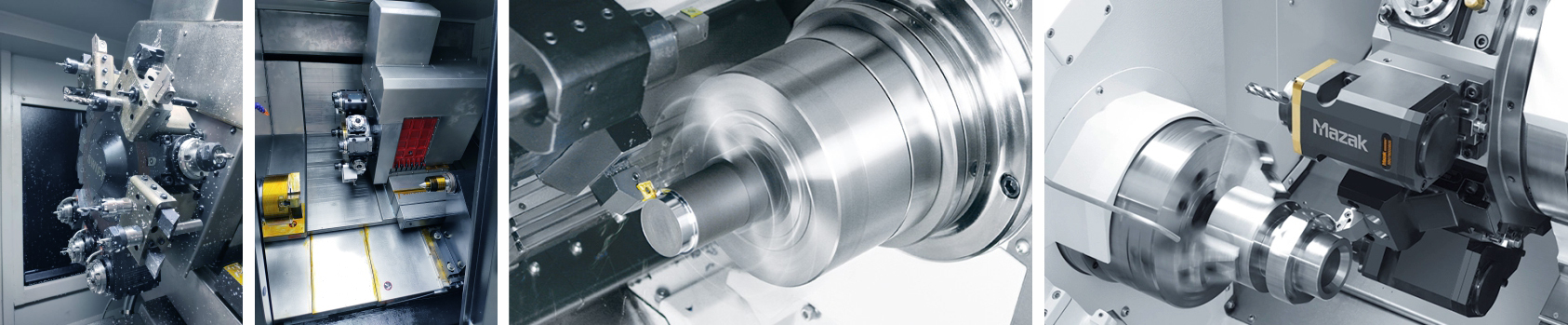

>CNC machining equipment |

|

|

In response to the high cleanliness of semiconductor pipeline fittings, the large size and high precision of photovoltaic fittings, and the complex and irregular structure requirements of non-standard vacuum chambers, the company has introduced equipment such as machining centers, CNC lathes, and high-speed drilling and tapping centers, covering the entire field from micrometer level precision machining to large-scale component forming. It can achieve interference free processing of complex surfaces, ensuring that the inner wall roughness of semiconductor pipe fittings is below Ra0.4 μ m; The milling and turning composite machine tool completes multi process machining with one clamping, controlling the coaxiality error of photovoltaic components within ± 0.005mm; The high-speed drilling center efficiently completes batch processing of hundreds of precision holes in the vacuum chamber at a spindle speed of 12000rpm, with an efficiency increase of 40% compared to traditional equipment.

Relying on these devices, Yuanhe has not only achieved ultra clean mass production of semiconductor pipeline fittings and high stability matching of photovoltaic modules, but also quickly responded to the customized needs of non-standard vacuum chambers in university laboratories. With the dual wheel drive of "equipment accuracy+process experience", it provides more reliable precision accessory solutions for cutting-edge industries worldwide.

>Robotic arm |

|

The company is led by "intelligent manufacturing empowers high-end equipment", introducing automated robotic arm equipment to comprehensively upgrade the precision manufacturing capabilities of semiconductor pipeline accessories, photovoltaic production accessories, and non-standard vacuum chambers. This device is equipped with a high-precision servo system and visual positioning technology, with a repeat positioning accuracy of ± 0.02mm. It can seamlessly adapt to the multi process turning and milling composite processing of semiconductor ultra clean pipe fittings, high-speed welding and inspection of photovoltaic accessories, and intelligent assembly of non-standard vacuum chamber irregular structures, greatly improving the processing consistency and yield of complex surfaces and micro cavities.

>Welding process and equipment |

|

We have plasma welding machines to overcome the welding difficulties of thick plates with stable heat input, ensuring the reliability of vacuum sealing meets scientific research standards. In addition, equipment such as argon arc welding machines and resistance welding machines work together to cover diverse welding scenarios ranging from micro precision parts to large components.

>Quality control |

|

Based on strict quality control, the company has established a multidimensional testing system to strengthen the quality defense line for its products. The company is equipped with various professional equipment such as testing instruments, covering key indicators such as material composition, dimensional accuracy, sealing performance, and surface cleanliness, to meet the strict requirements of semiconductor ultra clean environment, photovoltaic high-efficiency components, and laboratory high-precision scenarios.

Relying on a sound quality control process, implement full process control from raw material entry to finished product delivery: through a three-level quality inspection mechanism of first article inspection, patrol inspection, and final inspection, combined with statistical process control, dynamically monitor production deviations; Customize a specialized testing plan for the weather resistance of the product and the sealing reliability of the vacuum chamber to ensure stable and compliant product performance.